The sand maker, also known as sand making machine, has replaced traditional equipment, such as the hammer crusher, roll crusher, rod mill, etc. Artificial sand maker proves to be the most essential equipment in the artificial sand making industry.

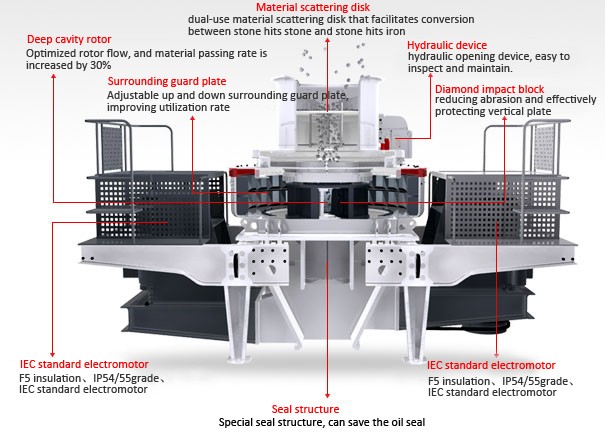

The VSI sand maker, also known as the impact crusher, has replaced traditional equipment, such as the hammer crusher, roll crusher, rod mill, etc. Artificial sand maker proves to be the most essential equipment in the sand making industry. The sand making machine in our company is developed by introducing the 'stones crush stones' working principle and technology from the United States and combining the actual domestic sand production conditions, making a leading high efficiency sand making equipment of world level.

.jpg)

.jpg)

.jpg)

Our company provides mainly three types of sand making equipment: the VSI5X sand making machine, the VSI sand maker and the PCL sand making machine.

1. The VSI5X sand making machine combines three modes into an organic whole. It is the core equipment in industries, such as architecture, mining, metallurgy industry, highway, railway, bridges, water and electricity, mineral powder milling field.

2. The VSI sand maker is the prior choice when selecting the whole system of sand making machines, widely used in highway, railway, high buildings, municipal engineering, hydropower dam construction, concrete mixing station. It can provide high quality manual sand aggregate, sand and stones.

3. The PCL system sand making machine is widely used in all kinds of ores, cement, refractory materials, bauxite clinker, iron, carborundum and glass raw materials of high-hardness and super-hardness for medium and fine crushing.

The materials falling to the artificial sand maker are divided into two parts by the distributor, with one part getting into the high-speed rotating impellers through the distributor, which are accelerated quickly in the impellers, reaching 100 times the acceleration of gravity, and then cast at the speed of 60 to 70 m/s from the three distributed passageways of the impellers and impacted by the materials falling around the distributor. Then they are impacted together with the lining in the cavity. Rebounded by the lining, those materials are sent obliquely upward to the top of the vortex cavity, and then they change the direction with a downward deflection, making a continuous material curtain. Therefore, the materials are impacted and crushed constantly in the vortex cavity. The crushed materials are discharged from the bottom port forming a closed circuit with the screening system. Generally, three times circulation can reach the granularity of 20 meshes. During the whole process, the materials are mutually impacted instead of contacting with the metal components, thus reducing the pollution and reducing the abrasion of the machine. Moreover, the self circulation of the air in the vortex cavity eliminates dust pollution.

| Model specification |

Max.feeding size (mm) |

Power (kw) |

Rotation speed of impeller (r/min) |

Capacity (t/h) |

Overall dimension (L×W×H) (mm) |

| HX-06 | 35 | 2P 37-55KW | 2000-3000 | 10-30 | 2500×1620×2600 |

| HX-07 | 45 | 4P 55-75KW | 1500-2500 | 20-55 | 2700×1760×2800 |

| Model | VSI 7611 | VSI 8518 | VSI 9526 | VSI 1140 | VSI 1145 | VSI 1150 | |

| Capacity (t/h) |

Feed both at center and sides | 80-180 | 140-260 | 200-380 | 300-520 | 350-610 | 360-650 |

| Feed at center | 40-90 | 70-130 | 100-190 | 160-260 | 180-355 | 190-365 | |

| Max.feeding size (mm) |

Soft material | 35 | 40 | 45 | 50 | 50 | 50 |

| Hard material | 30 | 35 | 40 | 40 | 45 | 45 | |

| Rotation speed(r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1150-1300 | 1150-1300 | 1150-1300 | |

| Motor power(kw) | 4P 110 | 4P 180 | 4P 264 | 4P 400 | 4P 440 | 4P 500 | |

| Overall dimension(L×W×H)(mm) | 4100×2250×2300 | 4160×2360×2500 | 4540×2500×2830 | 5500×2750×3100 | 5500×2750×3100 | 5500×2750×3100 | |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

You can also send a message to us by this email sales@hxjq.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!

You can also send a message to us by this email sales@hxjq.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!