The magnetic drum separator can separate raw materials with different magnetic rigidities. The China magnetic separator works under the magnetic force and mechanical force.

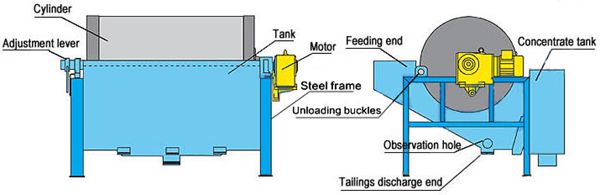

The China wet magnetic separator, also magnetic drum separator, can separate raw materials with different magnetic rigidities. The magnetic drum separator works under the magnetic force and mechanical force.

China Magnetic separator is designed to recover ferromagnetic materials. The magnetic drum separators are available in designs and sizes to provide solutions for all applications. The core part of each separator is the magnetic system with its unique design, which has a proven record of high efficiency. China wet magnetic separator is available in cyclic design with process vessel diameters smaller than 3mm. Wet magnetic separator is one kind of efficient equipment for processing fine, feebly magnetic minerals, such as hematite, limonite, wolfram and tantalum-niobium, etc. The wet magnetic separator is widely used for its powerful functions.

The mineral slurry flows into the cell through box feeder and the mineral particles will become loose under the function of water flow of water pipe when they flow into the cell. Affected by magnetic field, the magnetic particles swarm together and form magnetic cluster or chain. With the magnetism of mineral slurry, the magnetic cluster or chain moves toward the magnetic pole, and is absorbed to the cylinder. Because of the polarity of magnetic pole, the revolving directions alternate constantly, and remain fixed when working. When the magnetic cluster and chain go round and round along with the cylinder, the mingled gangue and other non-magnetic ore fall down due to the mixing phenomena produced by alternation of magnetic poles, and its concentrate is absorbed to the cylinder surface. The concentrate moves to the end of magnetic system where the magnetism is weakest along with the revolving cylinder, and is discharged into concentrate tank by the current ejected by the discharging-ore pipe. The non-magnetic or weak magnetic remained are discharged along with the mineral slurry, and become gangue.

Hongxing Machinery is one of the largest China magnetic separator manufaturers, leave us a message to get magnetic separator price?

| Model | Shell diameter (mm) |

Shell lenght (mm) |

Shell rotation speed(r/min) |

Feeding size (mm) |

Processing capacoty (t/h) |

Power(kw) |

| CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

| CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

| CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

| CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

| CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

| CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

| CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

| CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

| CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

| CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

| CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

| CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

| CTB1530 | 1500 | 3000 | <14 | 3-0 | 170-280 | 11 |

You can also send a message to us by this email sales@hxjq.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!

You can also send a message to us by this email sales@hxjq.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!